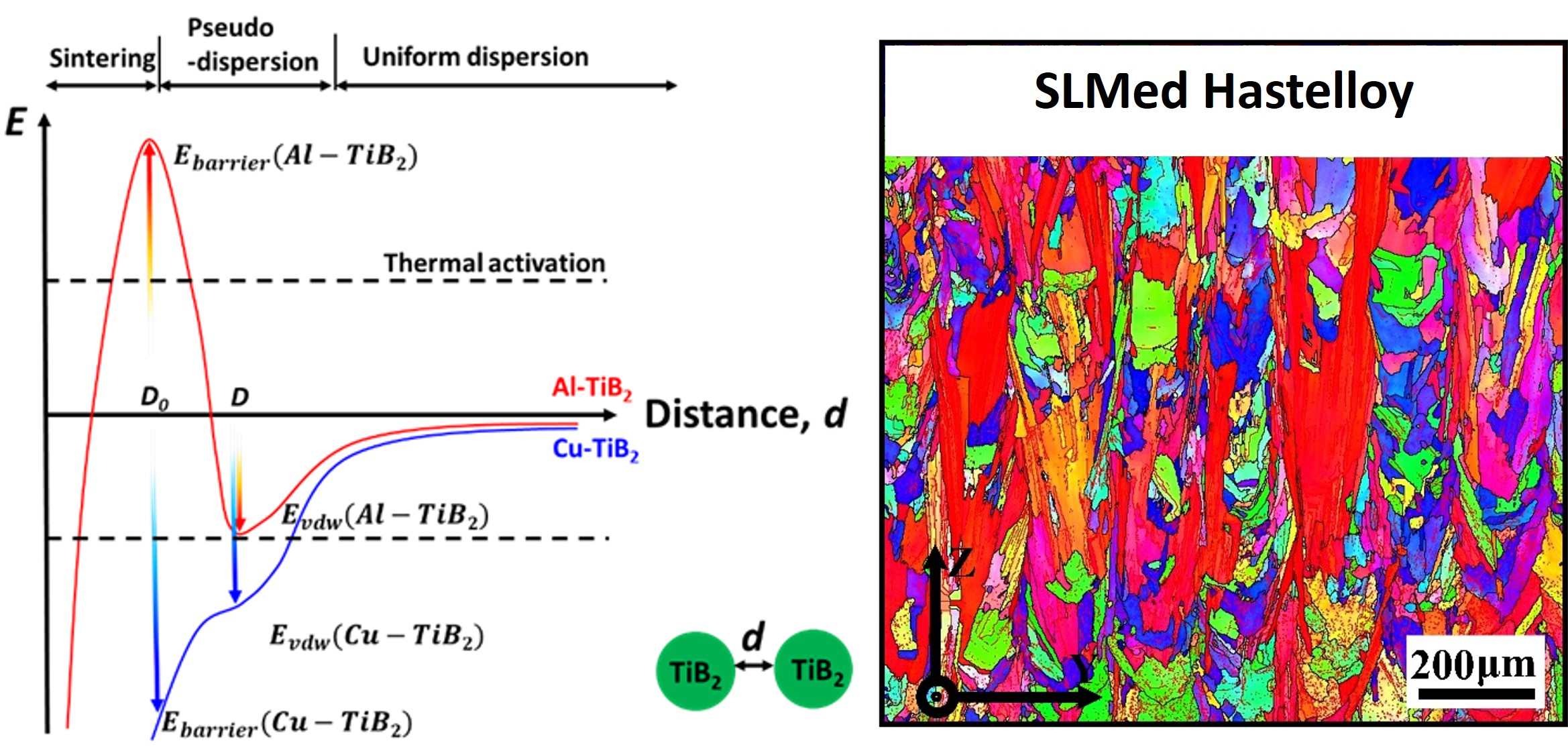

1. Advanced manufacturing of novel alloys

Advanced manufacturing for novel metal and alloy systems is more and more important. With the emerging additive manufacturing techniques, new opportunities have opened up.

LoAM will focus on: (1) Physics-guided novel alloy design; (2) Application-oriented additive manufacturing process optimization. Current alloy systems of interests include Al-, Ni-, Ti-, and Mg-alloys.

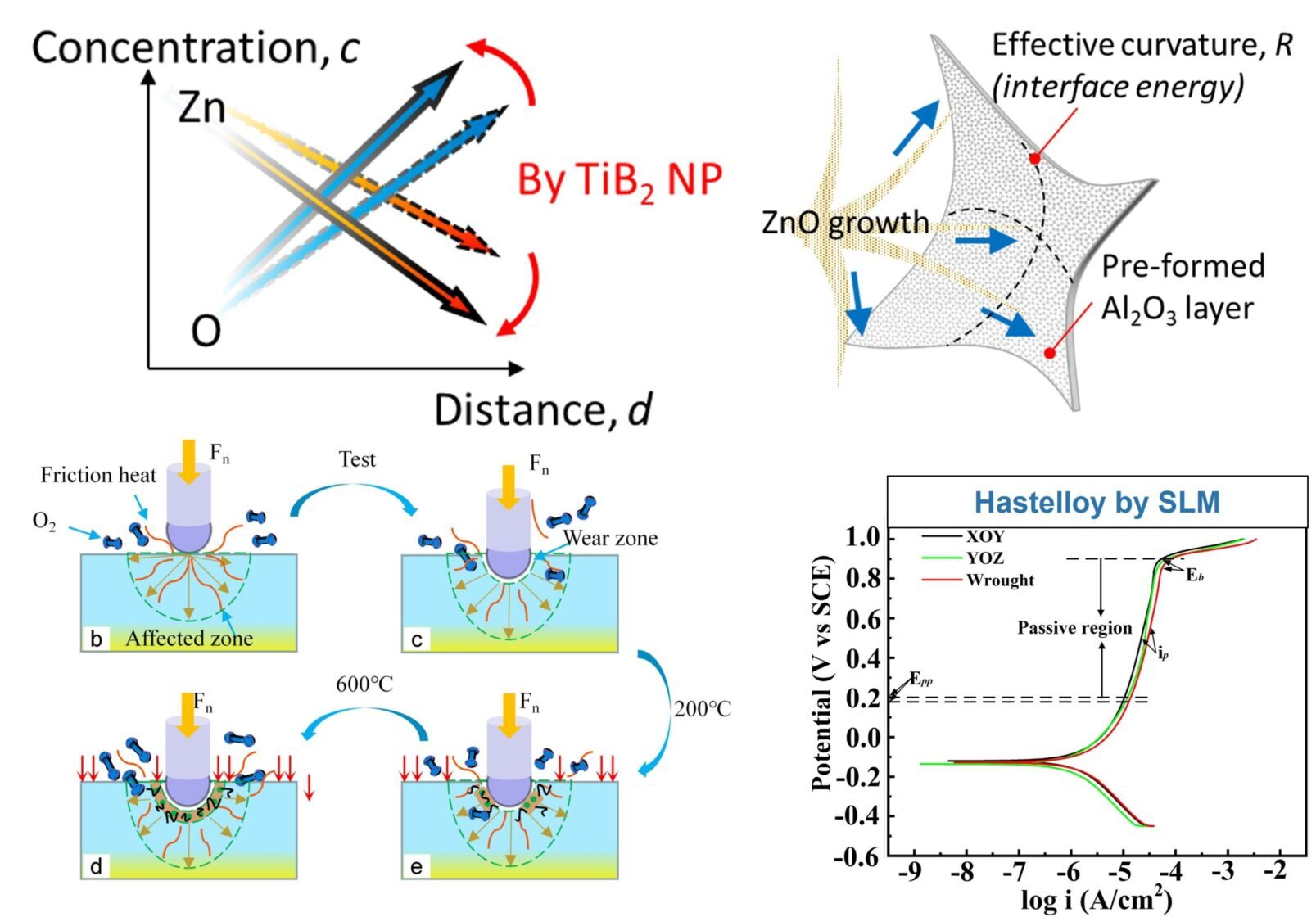

2. Anti-degradation design for AMed alloys

Alloys are generally susceptible to various degradation processes. Oxidation, wear, and corrosion are endangering the sustainability of AMed alloys.

LoAM is exploring the fundamentals and providing solutions for critical anti-degradation needs like extremely high-temperature stability, ultralow wear rate, and mitigated SCC susceptibility.

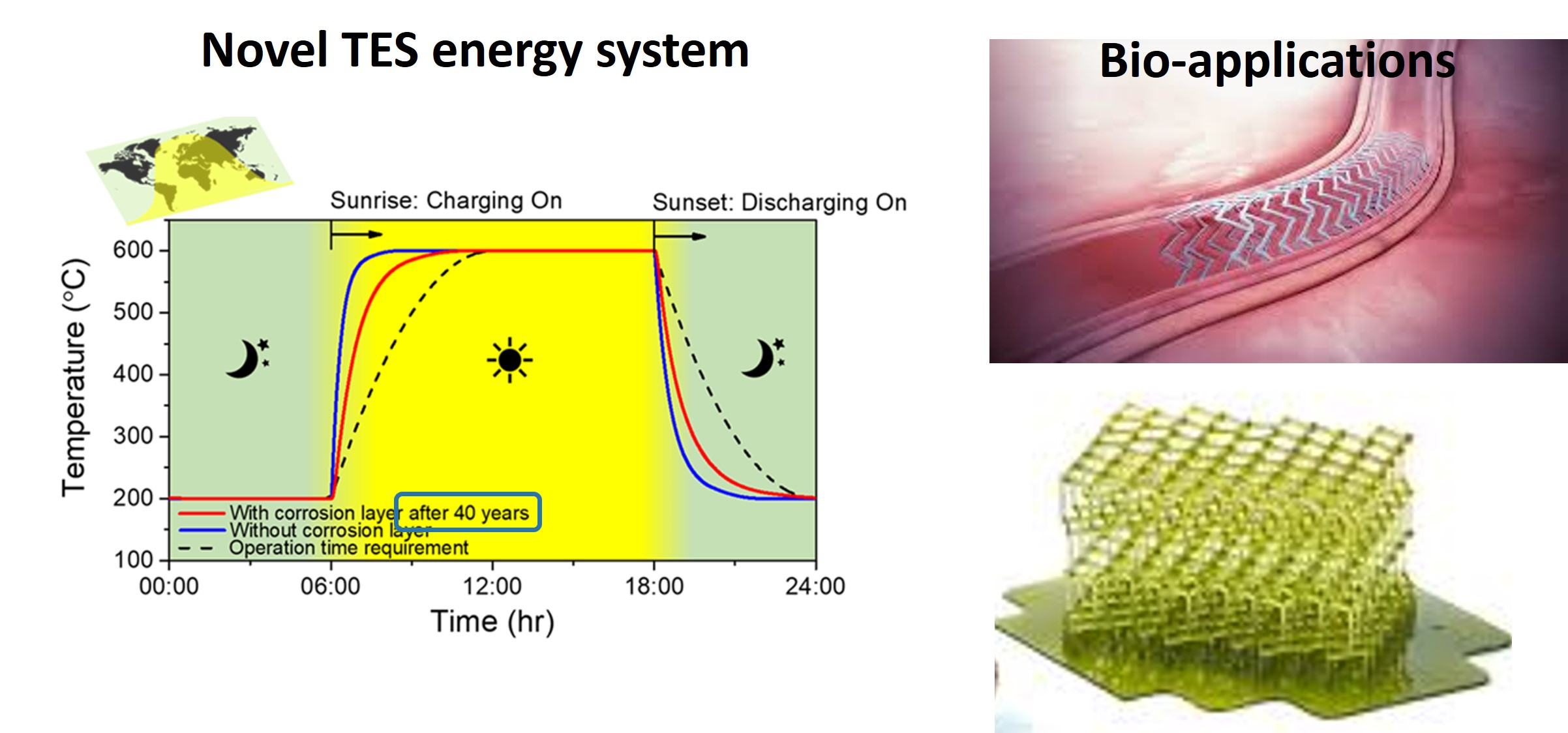

3. Applications with long-stability of AMed alloys

Currently, LoAM's development for AM-compatible and degradation-resistant metals and alloys have been applied in scenarios like:

Energy storage (novel sulfur-TES system), bio-devices (implant metallic parts and novel actuators for mini-robots), etc.

* Facilties

LoAM is equipped with advanced facilities and tools for every manufacturer:

Lab-owned facilities:

Heat treatment furnace

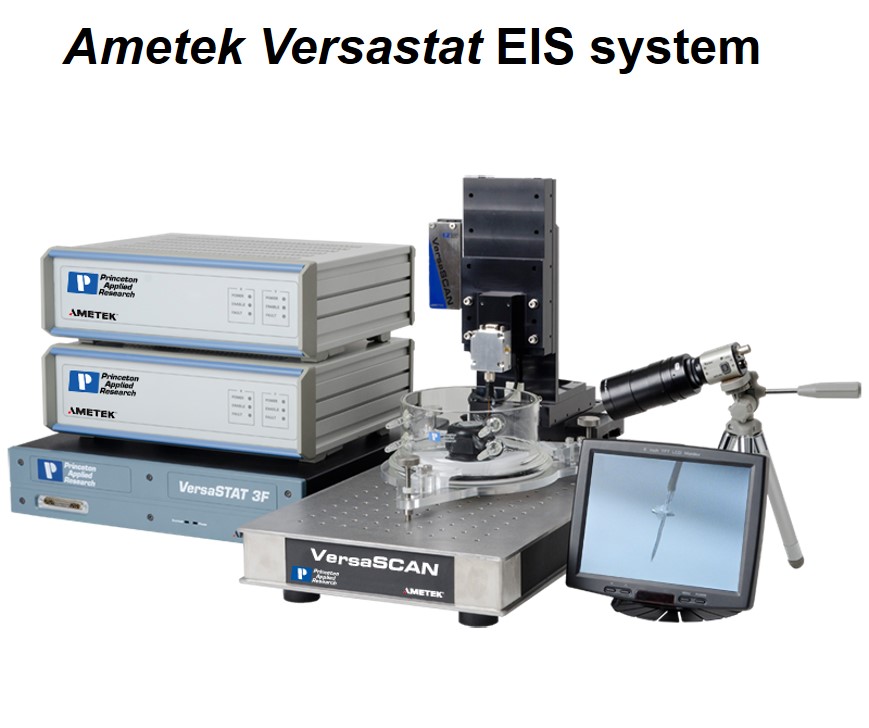

EIS corrosion test station (campatible with SKP setup)

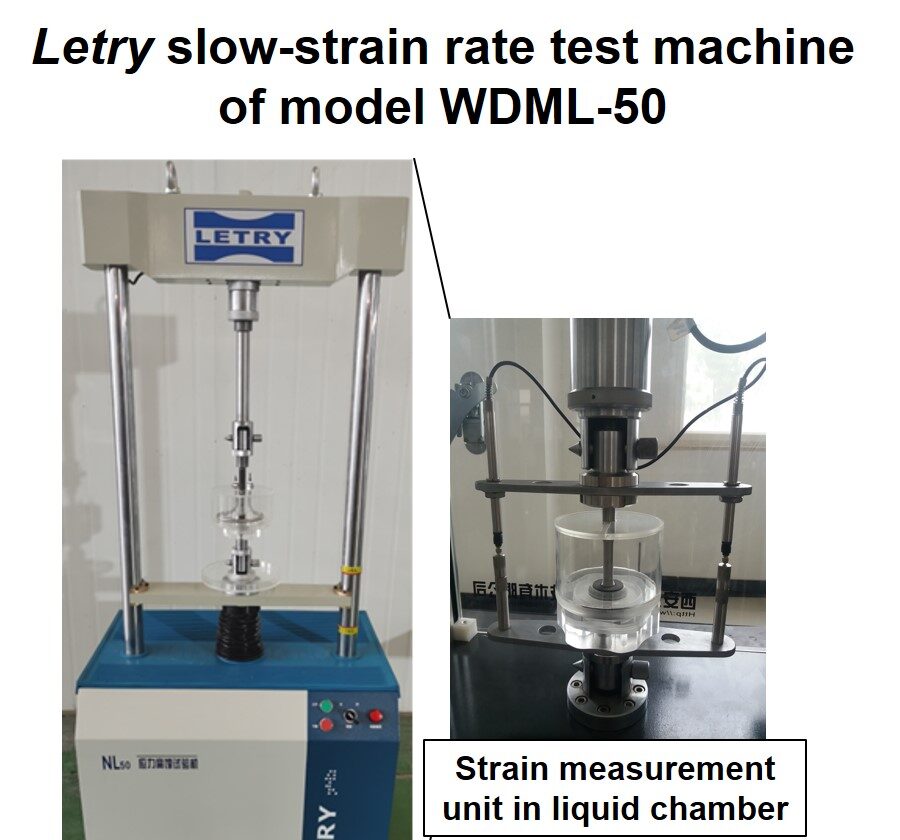

Slow strain rate test machine (for SCC and creep)

Shared facilties:

SLM machine (with in situ capacity)

Focused Ion Beam SEM (FIB-SEM) with EBSD

Scanning Transmission Electron Microscope (STEM)

in-situ Transmission Electron Microscope TEM (with liquid cell)

Atomic Force Microscope AFM)

X-ray Photoelectron Spectrometer (XPS)

Read more at: Utah Nanofab